Castlegate’s state of the art Steel Casting Foundry consists of

- In-house pattern shop

- Modern machine shop and Testing

- In-house facility backed by Generator

- Wind Power for non-stop production

- Installed capacity 3,600 tons per annum

- Maximum single piece weight 2,100 kg

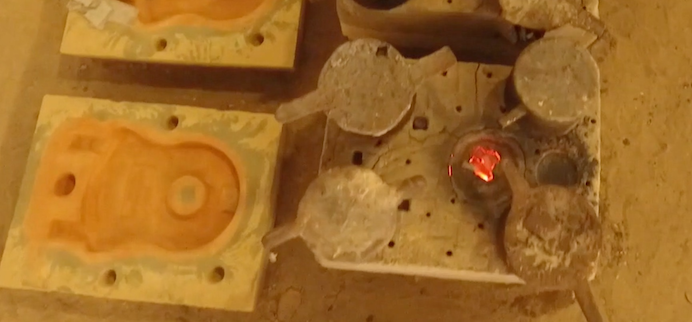

- Pattern shop features highly trained pattern makers from the simple to extremely complex casting design.

- Our patterns ensure accurate casting that meets Customer specifications.

- CNC machined patterns provide close & consistent casting tolerances.

- The Pattern shop is strengthened with dedicated CNC machine for full-time pattern making from solid models and Simulation software SOFT CAST 3.5 for the method.

- Sodium Silicate / CO2 & Resin bonded (No Bake)

- Shell Process

- Automatic water quenching furnace with 120,000-liter water capacity integrated with Agitating pumps.

- Furnace calibrated to API 6A and NORSOK M650.

- Certified by TUV and IBR.

- Three heat treatment furnaces each having a capacity of 5 tons.

- Full Fledged In-house Fettling

- Arc Cutting

- Gas Cutting

- Grinding

- Dressing Facility-Steel Shot Blaster

- Qualified and Approved sub-Contractors